click here to enlarge

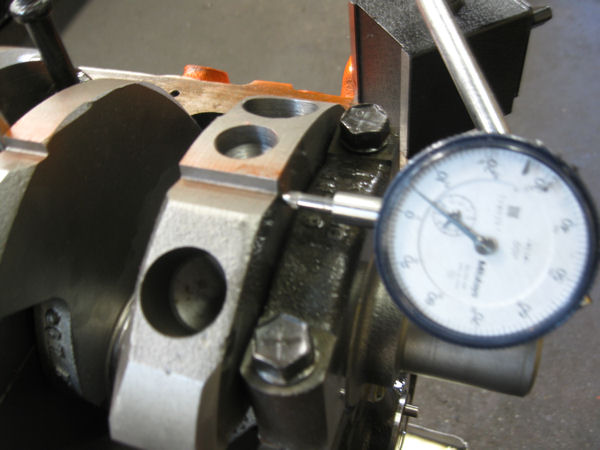

--all rod housing bores, new or used, are checked for roundness and size and redone if they are not within spec-

click here to enlarge

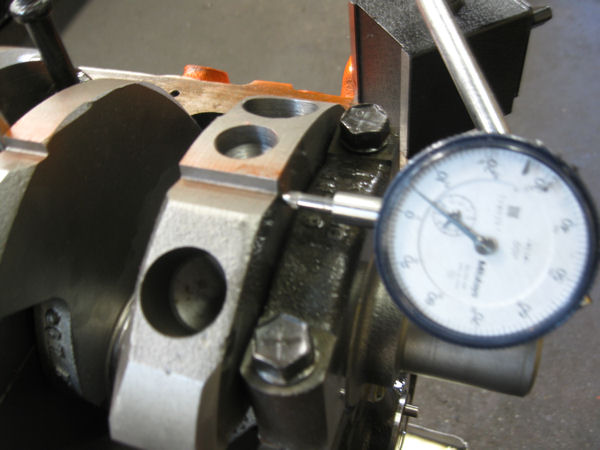

checking and setting thrust clearance is an important part of the assembly-too little will create heat and wear the thrust surface of the crank

click here to enlarge

-making sure that your hone finish is within the parameters of where it's suppose to be with a surface gauge insures a long lasting finish for the rings-

click here to enlarge

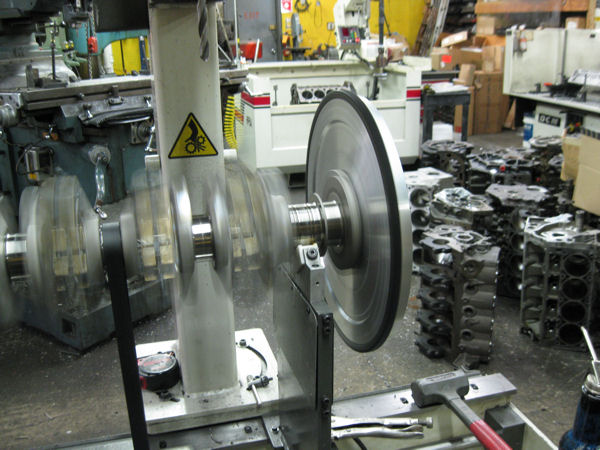

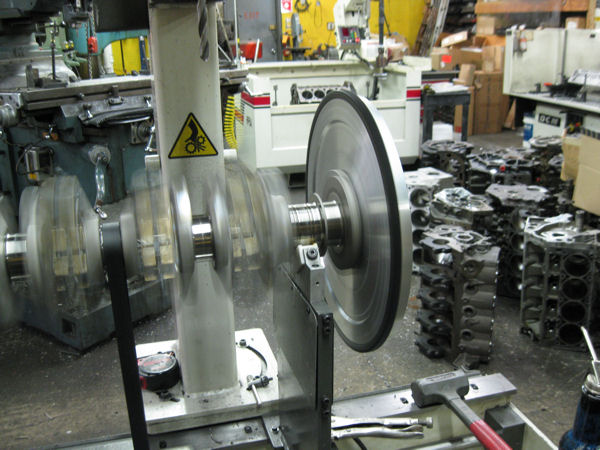

-balancing becomes necessary when the components being used are a different weight than the original components or if the assembly is new and hasn't been balanced previously-

click here to enlarge

-with 2 very accurate Sunnen gauges, one is setup to check the housing bores of the rods and the other is set to the size of the crankshaft rod journal for the ease of checking the bearing clearance w/o resetting the other gauge-

click here to enlarge

-prior to the assembly, checking cranks for any small scores or scratches is well worth the time spent and then a light polishing will ensure it's ready to go-

click here to enlarge

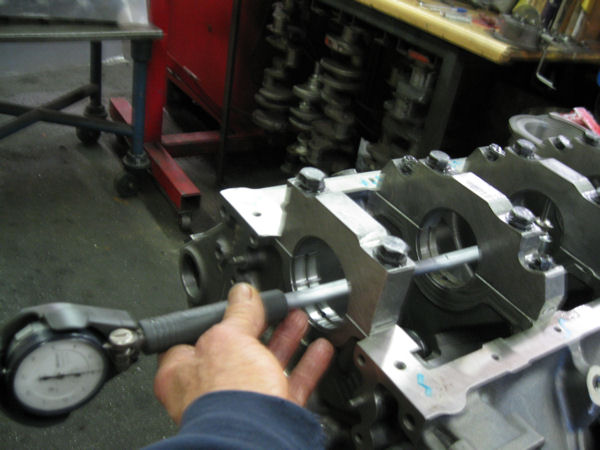

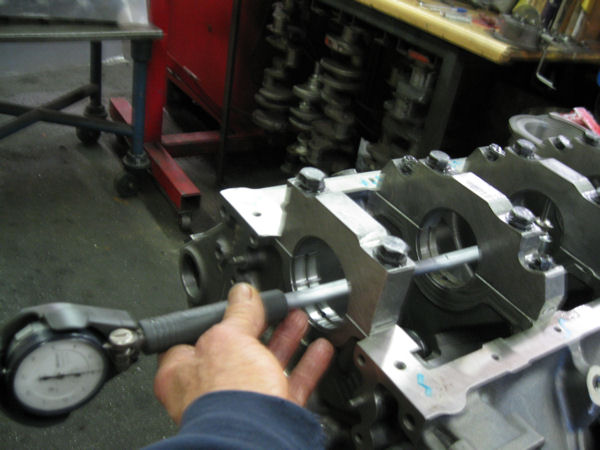

-checking the main bearing clearance after the mains have been align-bored is a necessity-even though all the housing bores are the same size there is often some thickness differences from bearing to bearing-nothing should be overlooked when doing preassembly checking-it only takes one item to be overlooked for a problem to develope-

click here to enlarge

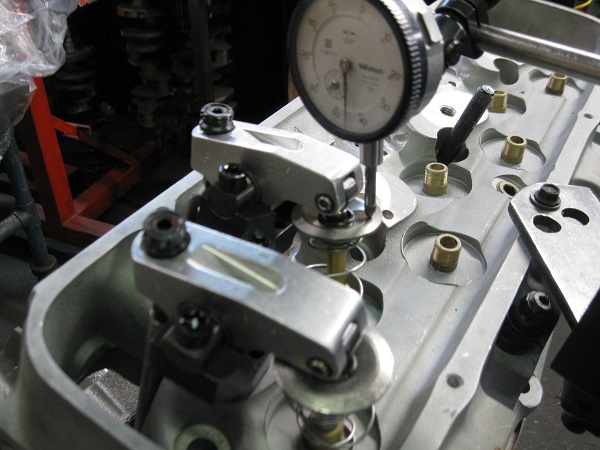

-adjustable pushrod and checking spring allows you to try a couple of different lengths to help you choose the correct one for the best rocker geometry-

click here to enlarge

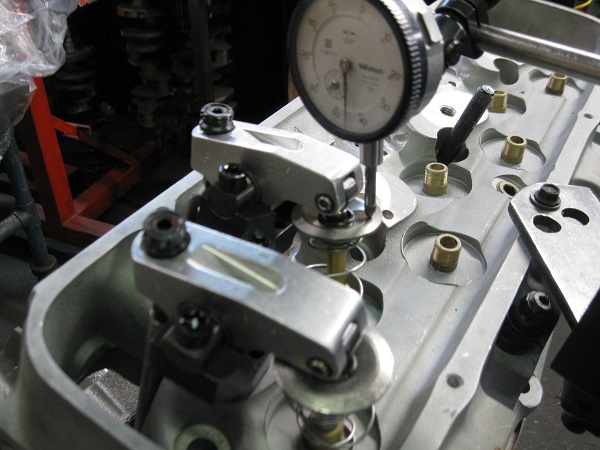

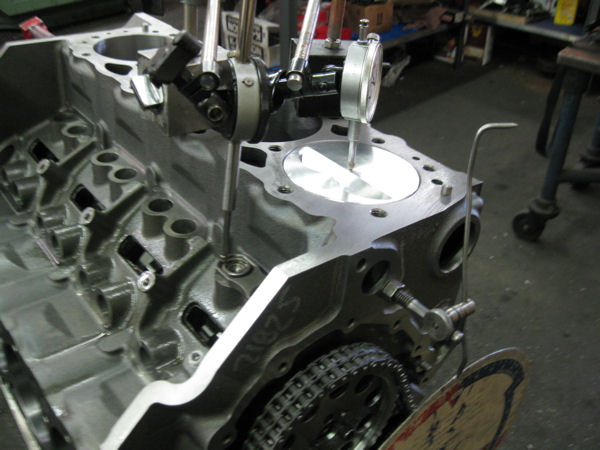

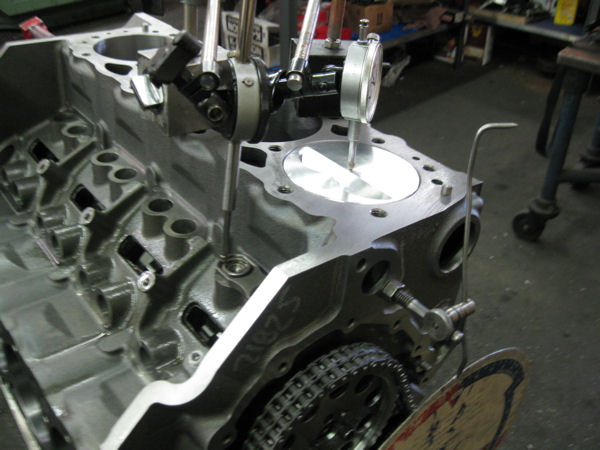

-if you're using a large or aggressive camshaft, you might want to check the clearance between the valve and piston-easiest and most accurate way is with light checking springs and a dial indicator and pushing the valve down to find the closest point--

click here to enlarge

-after finding that you are coming up a little short on the valve to piston clearance, flycutting the piston reliefs will be necessary to help you reach that long lasting combination--

click here to enlarge

-torquing the rod bolts to the proper stretch will keep the fastener tight-

click here to enlarge

checking ring gap is a vital part of the engine building operation-the ring gap is determined by the usage, whether it's NOS, Forced Induction or just N/A operation, each specific load will have it's own gap dependent upon the heat deilvered and the bore size-

click here to enlarge

-degreeing a camshaft to the correct intake center or at least knowing what centerline you are installing the cam at, becomes a very helpful tuning element to move the power curve, either up or down, to put the power where the car needs it most-

click here to enlarge

-old but invaluable gauge for comparing rod length from one rod to the next and also for checking connecting rod straightness-

click here to enlarge

-making sure that the surface finish on heads and blocks is smooth enough for the MLS gaskets is critical for the sealing effect

our facebook page

our facebook page