click here to enlarge

--Pressure Testing--after all the water jackets of the head or block are plugged, 40 -60 lbs of air pressure is tapped into the water system and then the head is sprayed with a soapy solution and if there is a crack it will start to weep air bubbles--one of the first operations that should be done to a core if you don't know anything about it before any money is invested--

click here to enlarge

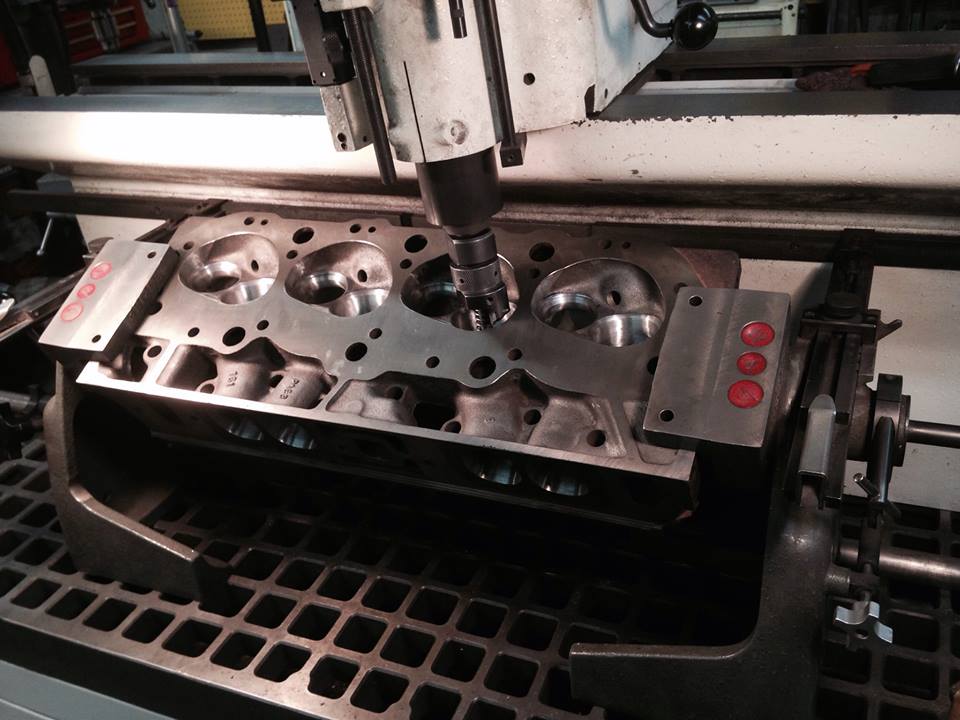

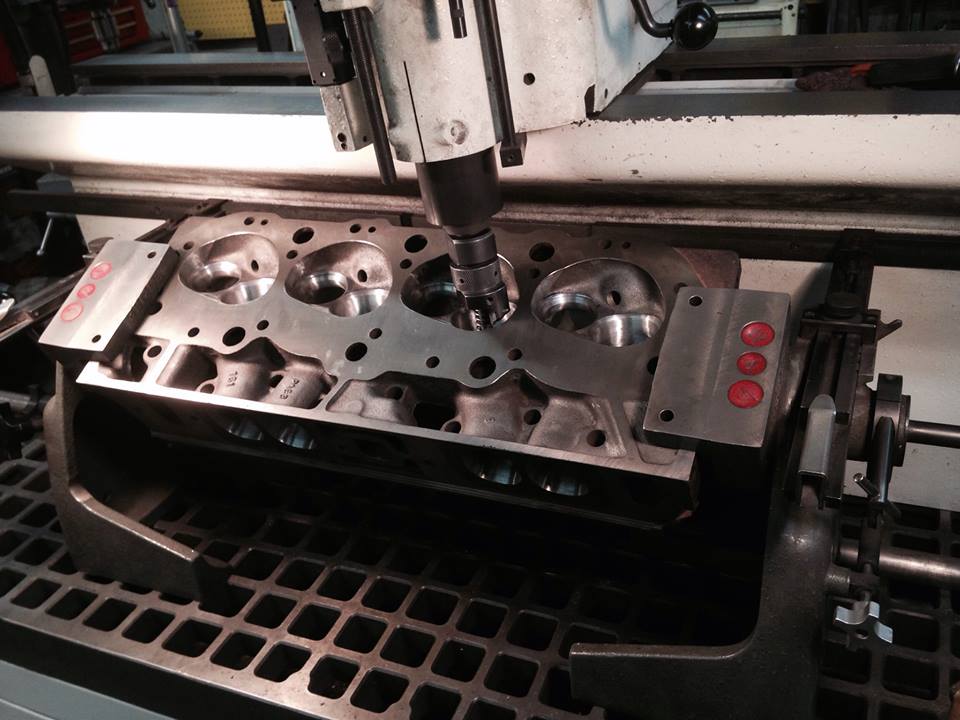

-Cylinder Head Milling--the DCM HB 3800 uses high speed CBN cutters to mill the cylinder head to correct any warpage due to a blown head gasket or to correct any deviations that will hinder the head gasket from sealing effectively--The RA finish is well under the required factor to use a MLS head gasket--the milling operation can also be done to achieve more compression by lowering the cc's in the combustion chamber--

click here to enlarge

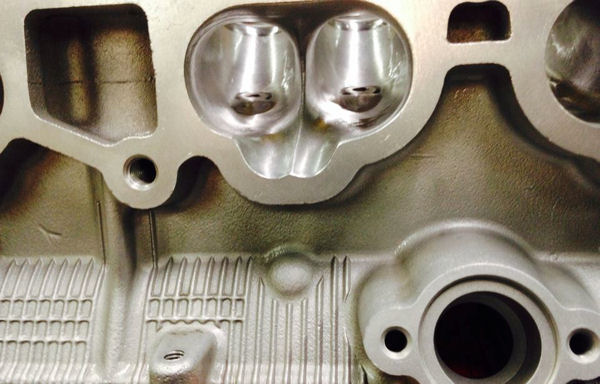

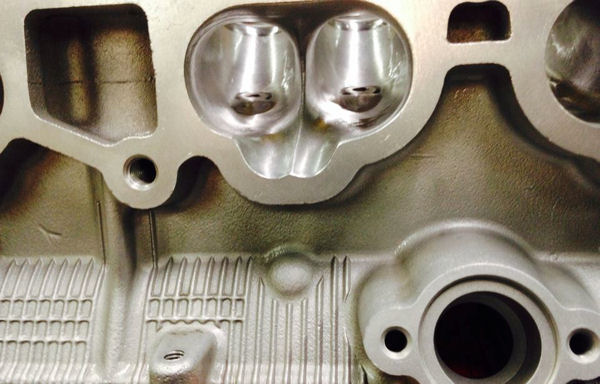

--Competition Valve Job--this operation is completed on a Sunnen VGS 20 that can use all in one fixed cutters such as 30°/45°/60° or you can do a series of custom angles that we have found on the flowbench to be quite an inprovement in flow over the original angles--valve seat runout is always checked but not usually a problem since we use the very stiff titanium pilots that have very limited movement--

click here to enlarge

--FlowBench Testing--testing a cylinder head and finding some areas that need airflow improvement can really make HP come alive in an engine--a lot of popular domestic cylinder heads on the market today are available with CNC'd ports to give us a great airflow right out of the box but we still have a large call for port work on a lot of imports as well as domestics being used as street machines, road race, and drag cars--

click here to enlarge

Porting a cylinder head is the best way to open the door for increased airflow and as a result of that, more hp and rpm--

click here to enlarge

--Rimac Valve spring gauge will insure that the valve spring pressure is correct for each style camshaft being used and also checking for valve spring coil bind--

click here to enlarge

In order to determine an engines exact compression ratio--CC-ing a combustion chamber, along with the deck height measurement, head gasket thickness and bore diameter of the actual gasket, cylinder bore and stroke, will be necessary--

click here to enlarge

even though this is a forced induction application, porting a cylinder head will increase the overall volumetric efficiency thru the entire RPM band yielding more hp yet--

--Cutting Valves--The Kwik Way valve grinding machine can check valves for any erratic runout and redress them to the desired angle as long as the runout isn't too severe--

click here to enlarge

--Checking Valve Guide Clearance--the tool in this operation is a Sunnen valve guide gauge that measures in ten-thousands .0001, often referred to as tenths and will check the actual clearance in the valve guide-if the guide is too loose, it is very difficult to seat the valves with any degree of accuracy because the pilots that center the valve seat cutters can't center correctly--

--Valve Guide Sizing--the machine in this operation is a Sunnen HS-30 diamond guide hone that uses numerous diamond hone mandrels to cover the guide sizes in todays market--honing the guide with these mandrels makes life a lot easier to get the proper clearance than having a ton of individual reamers that aren't very effective for some of the bronze guides materials that we use

our facebook page

our facebook page