click here to enlarge

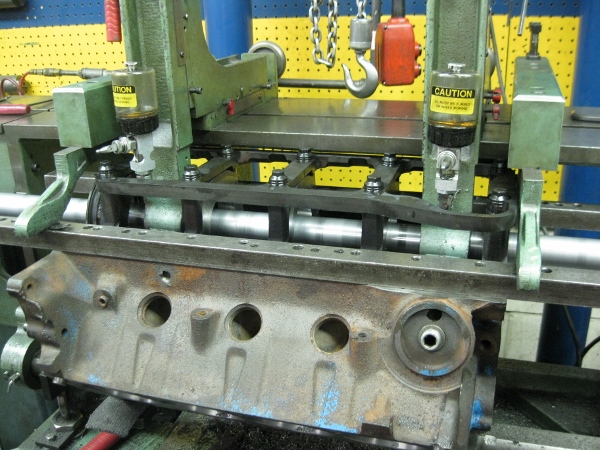

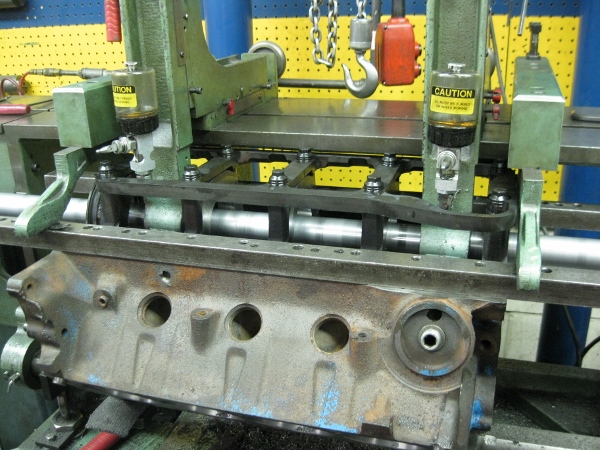

-align boring is one of the first machining operations performed and this ensures an accurate centerline for the crankshaft and also controls the size of the housing bore that makes it easier to establish main bearing clearance and proper crush on the main bearings-this ford block will be align bored with the Canton girdle in place-

click here to enlarge

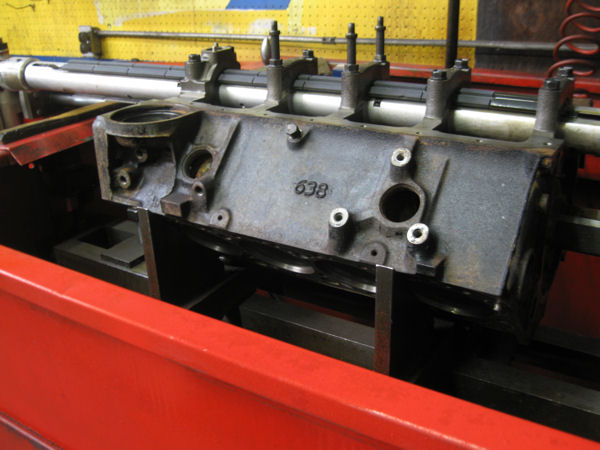

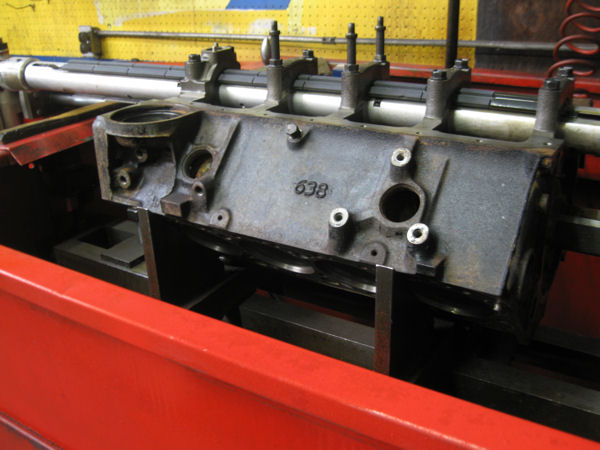

align honing can also correct main housing bore alignment if it is not too far out of bounds, but we use the sunnen align hone mostly to slightly increase the main housing bore size after align bore to put it at the proper spec for the desired clearance

click here to enlarge

Once we have align bored the mains, we can accurately mill the cylinder block to the correct block height using centering rings and a BHJ block tru fixture that locates off the align bored main housing and allows us to establish the correct deck height for the desired piston deck height to establish the proper compression

click here to enlarge

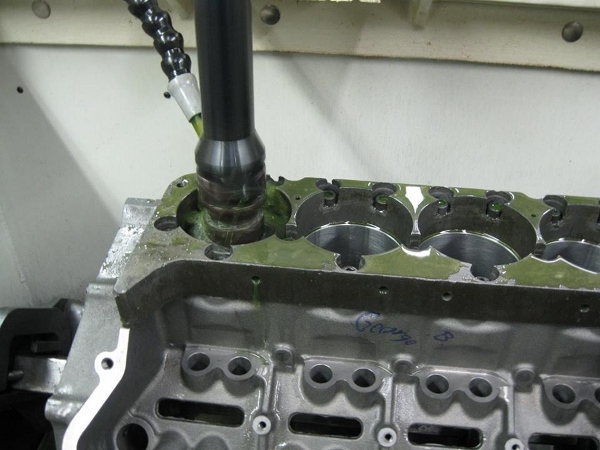

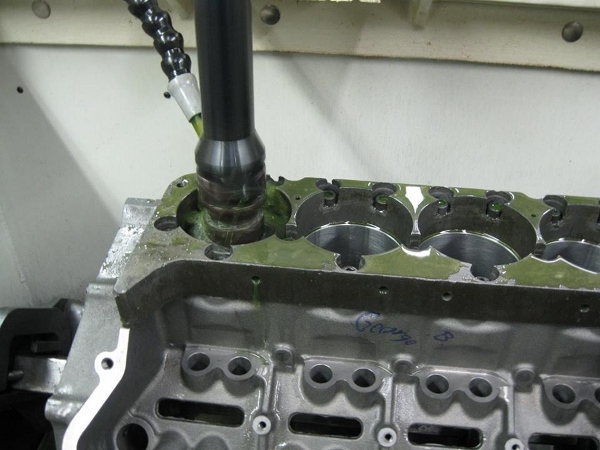

After the decking operation, we'll continue with boring the cylinders to the correct size and alignment--this operation is also performed with equipment that also locates and centers the cylinder alignment angle off of the main housing bore

click here to enlarge

Honing with one of the latest computer controlled diamond honing machines has offered technology and consistency--also allows us to use the latest input on plateau honing to give us some of the most desirable finishes for n/a or forced inductions

click here to enlarge

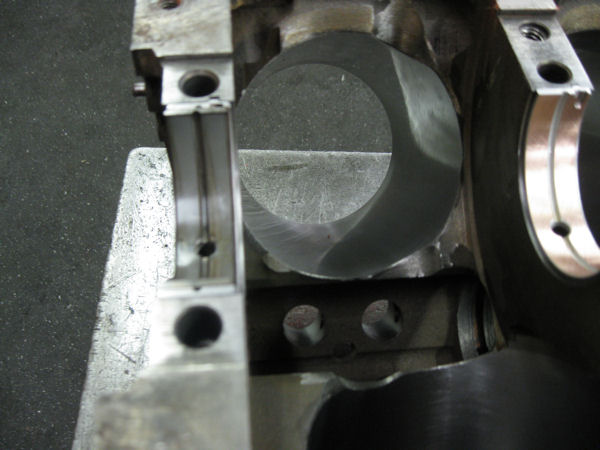

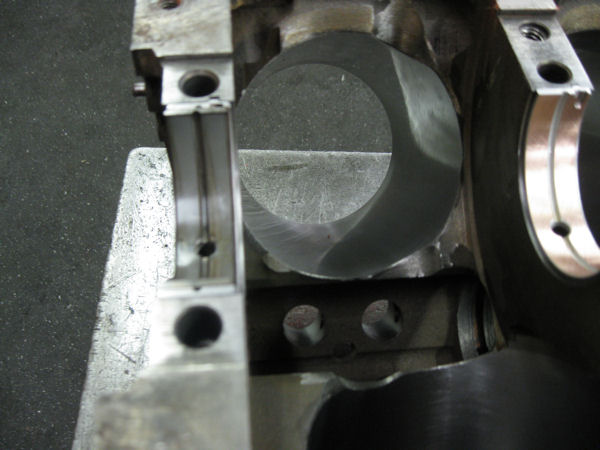

this pic may be a little hard to see, but in the 1st main notice a 350 main bearing located on top of the machined 400 main bearing as compared to the 2nd main which only has the machined 400 bearing--this accomplishes a couple of advantages: 1. it reduces bearing diameter friction and 2.the 400 grooved main bearing under the 350 main bearing will have oil to actually keep the 350 main bearing cooler-this operation was started back in the late 70's and still goes on today--

click here to enlarge

Dart block having lifter bores machined for a larger lifter bore diameter

click here to enlarge

pictured is a cylinder that is cracked being sleeved for a repair-although it looks pretty bad, after boring the rest of the block, it turned out fine

click here to enlarge

4G63 getting serious with this girdle--

our facebook page

our facebook page